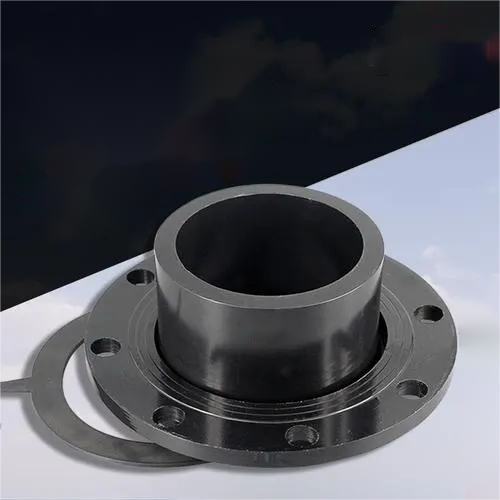

I-TS EN 1092-1 Slip Ku-Plate Flange Yensimbi Engagqwali Welding Flange

Isethulo Sesithombe

Idatha Yomkhiqizo

| Slip Ku-Plate Flange | |||||||||

| Okubalulekile | Insimbi ye-carbon | I-ASTM A105. I-ASTM A350 LF1. LF2, CL1/CL2, A234, S235JRG2, P245GH | |||||||

| Insimbi engagqwali | I-ASTM A182, F304/304L, F316/316L | ||||||||

| Okujwayelekile | BS 4504 | PN2.5-PN40 DN10-DN2000 | |||||||

| Ubuso | Amafutha angagqwali, i-lacquer ecacile, I-lacquer emnyama, i-Lacquer ephuzi,I-galvanized efakwe ashisayo, i-galvanized kagesi | ||||||||

| Ukuxhumana | Welding, Threaded | ||||||||

| Ezobuchwepheshe | Forged, Casting | ||||||||

| Usayizi | I-PN10-PN16, DN10-DN600 | ||||||||

| Iphakheji | 1. Ikesi Lokhuni 2. Njengezimfuneko Zamakhasimende | ||||||||

| Izinhlelo zokusebenza | Imisebenzi yamanzi, imboni yokwakha umkhumbi, imboni yePetrochemical & Gas, imboni yamandla, imboni yeValve, kanye namaphrojekthi ahlanganisa amapayipi ajwayelekile njll. | ||||||||

Isingeniso Somkhiqizo

I-Slip on plate flange ibhekisela ohlotsheni lwe-flange oluxhunywe nepayipi nge-fillet weld. I-Slip on plate flange iyi-flange engavamile. Uma kuqhathaniswa ne-neck butt welding flange, i-slip ku-plate flange inesakhiwo esilula futhi incane, kodwa ukuqina kwayo nokubekwa uphawu akukuhle njengeintamo izinqe welding flange. I-Slip on plate flange isetshenziswa kabanzi ekuxhumekeni kwemikhumbi namapayipi okucindezela okuphakathi nendawo nokuphansi. Ngoba inani leslip on plate flangelikhulu epayipini lokucindezela, kodwa ukuqina kwalo akulungile, akufanele lisetshenziswe epayipini elinengcindezi ephezulu, ipayipi elivuthayo neliqhumayo kanye nepayipi lenqubo yamakhemikhali elinezidingo eziphezulu ze-vacuum.

I-Slip on plate flange evame ukusetshenziswa ekhaya nakwamanye amazwe: Izindinganiso ze-Ministry of Chemical Industry: HG/T20592-2009, HG/T20615-2009; Izinga laseMelika: ASME B16.5, ASME B16.47; Amazinga kazwelonke: GB/T9124.1-2019, GB/T9124.2-2019.

Okujwayelekile kokushelela ku-plate flange

I-Flange iwuhlobo lwento yokuxhuma imishini ekwazi ukubona ukuxhumana nokuhlanganisa amapayipi nezingxenye phakathi kwemishini. Isetshenziswa kabanzi kugesi, i-petrochemical, imithi, i-metallurgy, iphepha, amandla, ukufingqa, ukwelashwa kwamanzi nezinye izimo zokusebenza zezimboni. Njengamanje, i-flange yokusika eshisayo yiyona ehamba phambilii-flange evamileifomu emakethe, futhi kungenye yezindlela ezijwayelekile ezisetshenziswa ezindleleni ezihlukene zokucubungula ukuxhumana

Njengesibonelo sokucutshungulwa kwe-flange okushisayo kunesiqinisekiso esikhulu ngokunemba nokuvinjelwa kwemishini, leli phepha ligxile kakhulu ku-flange eyenziwe nge-steel plate, engahlukaniswa ibe izingxenye ezimbili: i-flange welding flat kanye ne-extrusion flange.

I-flange ye-welding flat yakhiwe ngesisekelo sokusika nokusika imiphetho, futhi amapuleti ensimbi emaphethelweni ahlanganiswe ngokuqinile ngokushisela ukuze akhe isakhiwo sonke.

Izinyathelo eziyinhloko ze-flange welding flange processing zimi kanje:

(1) Khetha ipuleti lensimbi elifanele: lapho ushintsha usayizi wokubekezelelana, sicela ucabangele ngokucophelela usayizi wepuleti yensimbi ekhethiwe

(2) Ukusika nokugunda: sebenzisa umshini wokusika ipuleti lensimbi kanye nomshini wokupholisha ukusika ipuleti lensimbi ukuze kuzuzwe ukunemba kobukhulu kanye nezidingo zokulinganisa.

(3) Ukushisela kwepuleti lensimbi: sebenzisa ukushisela kwe-arc eqondile, qinisa unqenqema lwepuleti lensimbi nge-clamp encane, bese wengeza i-weld emile ekushiseleni.

(4) Ukuhlanganiswa nokulungiswa: faka futhi ulungise ama-bolts ahlukahlukene ukuze uqinisekise ukulinganisa kanye nesiqondiso sosayizi nentambo kuyahambisana.

(5) Ukuhlola: I-Vernier caliper isetshenziselwa ukukala ubukhulu be-flange, ububanzi bangaphandle nobubanzi be-weld. I-Vernier calipers isetshenziselwa ukukala usayizi we-flange.

(6) Ukupholisha: ukupholisha izikhala zonqenqema ukuthuthukisa ukubukeka kwesithombe.

Zonke izinsizakalo zokucubungula ezingenhla zama-flange welding welding ezenziwe ngamapuleti ensimbi zizocutshungulwa ngokuvumelana nezidingo zezindinganiso zomkhakha ukuze kuqinisekiswe ukuthi umkhiqizo ngamunye nokunyathelisa epuletini lensimbi kuhlangabezana nezidingo zobuchwepheshe. Ngesikhathi esifanayo, qinisekisa ukuthi izidingo zesici sokuphepha, ukubukeka nokuqina komkhiqizo kungahlangatshezwana nazo.

1.Nciphisa isikhwama–> 2.Ibhokisi Elincane–> 3.Ibhokisi–> 4.Ikesi lePlywood Eliqinile

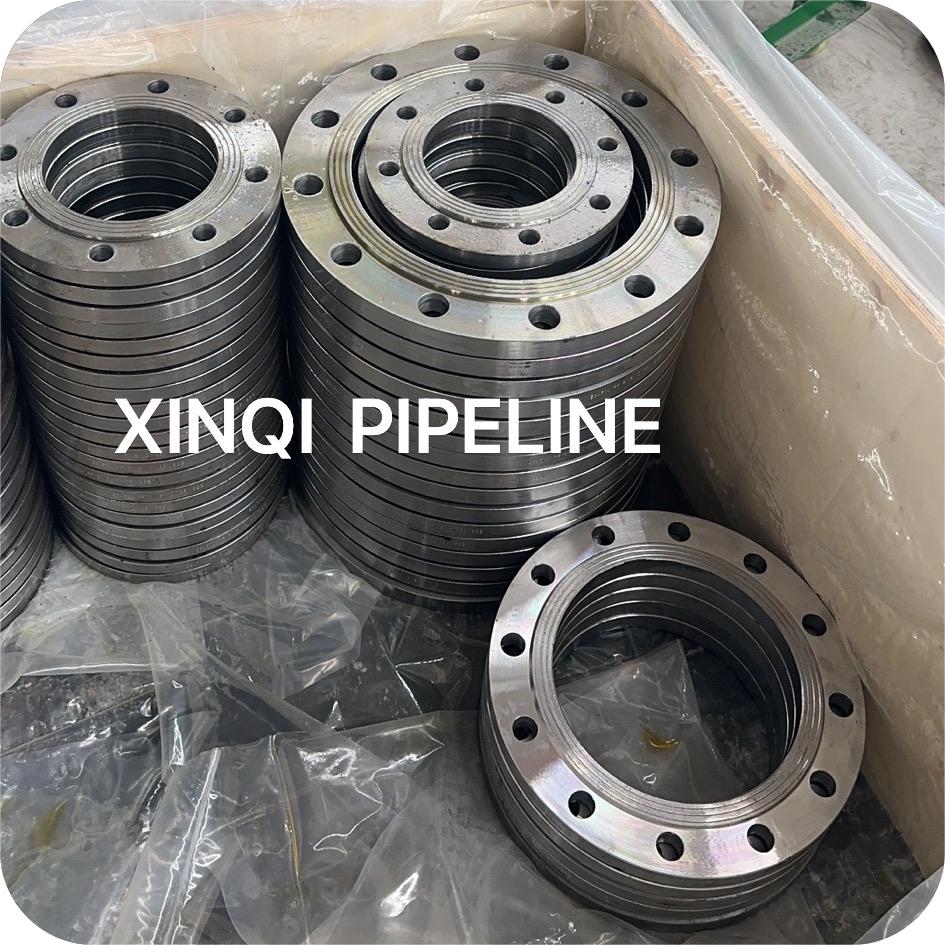

Enye yesitoreji sethu

Iyalayisha

Ukupakisha nokuthunyelwa

1.Ifektri yokukhiqiza.

2.Imiyalo yesilingo yamukelekile.

Isevisi ye-3.Flexible futhi elula yokwenza izinto.

4.Intengo yokuncintisana.

5.100% ukuhlolwa, ukuqinisekisa izakhiwo mechanical

Ukuhlolwa kwe-6.Professional.

1.Singakwazi ukuqinisekisa impahla engcono kakhulu ngokusho kwekhotheshini ehlobene.

2.Ukuhlola kwenziwa ekufakeni ngakunye ngaphambi kokulethwa.

3.Wonke amaphakheji avumelana nokuthunyelwa.

4. Ukwakheka kwamakhemikhali okubalulekile kuhambisana nezinga lamazwe ngamazwe kanye nezinga lemvelo.

A) Ngingayithola kanjani imininingwane eyengeziwe mayelana nemikhiqizo yakho?

Ungathumela i-imeyili ekhelini lethu le-imeyili. Sizohlinzeka ngekhathalogi nezithombe zemikhiqizo yethu ukuze uthole ireferensi yakho.Singakwazi futhi ukukuhlinzeka ngokufakwa kwamapayipi, ibhawodi namantongomane, ama-gaskets njll. Sihlose ukuba umhlinzeki wakho wesixazululo sesistimu yamapayipi.

B) Ngingawathola kanjani amasampula?

Uma udinga, sizokunikeza amasampula mahhala, kodwa amakhasimende amasha kulindeleke ukuthi akhokhe imali esheshayo.

C) Ingabe uyazinikeza izingxenye ezenziwe ngokwezifiso?

Yebo, ungasinika imidwebo futhi sizokhiqiza ngokufanele.

D) Iliphi izwe olethe imikhiqizo yakho?

Sinike iThailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine njll. (Izibalo lapha faka kuphela amakhasimende ethu eminyakeni emi-5 yakamuva.).

E) Angikwazi ukubona izimpahla noma ukuthinta izimpahla, ngingabhekana kanjani nobungozi obuhilelekile?

Uhlelo lwethu lokuphatha ikhwalithi luhambisana nemfuneko ye-ISO 9001:2015 eqinisekiswe yi-DNV. Sikufanele ngempela ukuba usithembe. Singamukela i-oda lesilingo ukuze sithuthukise ukwethembana.

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

Phezulu